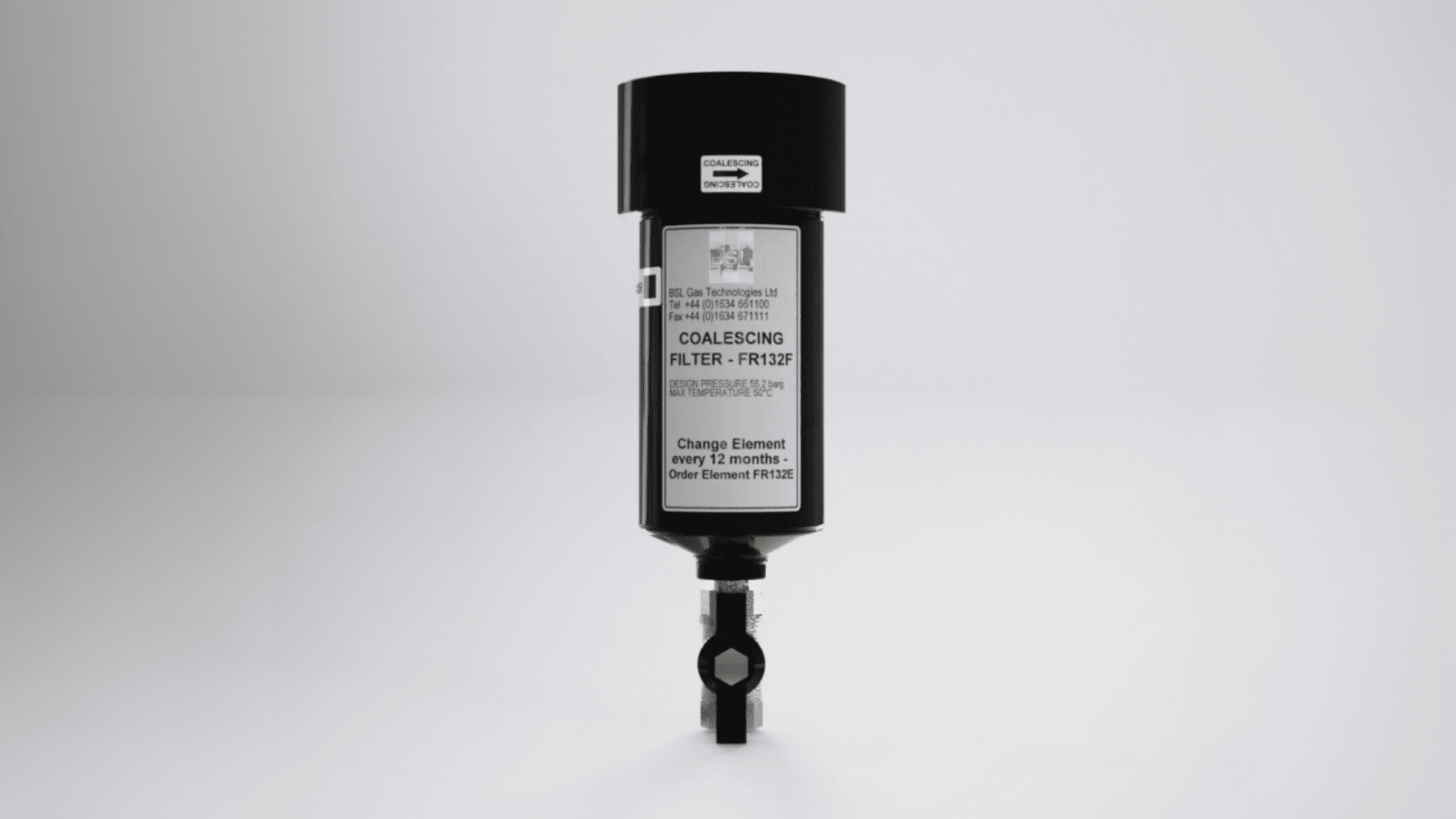

Adsorbing Filters

FR133F & FR163F Adsorbing Filters

Our adsorbing filters are specifically engineered for hydrocarbon removal from all the major gases used across industrial and commercial applications.

Dimensions

FR133F:

200 mm x 82 mm x 82 mm

FR163F:

260 mm x 83 mm x 83 mm

Weight

FR133F:

1 kg

FR163F:

1.5 kg

Supply Gases

All common industrial gases

Micron Size

0.01 microns

Inlet and Outlet Threads

G1/2 with optional G1/4 adaptors

Replacement Elements

FR133E

FR163E

-

All gas mixing products supplied by BSL Gas Technologies Ltd are produced in accordance with a BS EN 1SO 9001:2015 accredited quality system.

All gas mixing products supplied by BSL Gas Technologies Ltd are produced in accordance with a BS EN 1SO 9001:2015 accredited quality system.

BSL Adsorbing Filters

What are the key features?

-

Removable bowls for easy filter change

Removable bowls for easy filter change

-

Ready to use straight out of the box

Ready to use straight out of the box

-

Bottom drain option

Bottom drain option

-

Ensures gas systems remain moisture and hydrocarbon free

Ensures gas systems remain moisture and hydrocarbon free

-

Simple installation

Simple installation

-

Easy maintenance

Easy maintenance

What do BSL adsorbing filters do?

Adsorption is a process where gas molecules adhere to the surface of a solid material. The filter typically consists of a porous material, such as activated carbon, with a large surface area per unit volume. This high surface area provides ample sites for gas molecules to attach to, effectively removing them from the air or gas stream passing through the filter.

Our adsorbing filters are specifically engineered for hydrocarbon removal from all the major gases used across industrial and commercial applications. Designed for precision, these filters are exceptionally effective in capturing and eliminating hydrocarbons, which can pose serious contamination risks and operational challenges if left unchecked.

In industries such as pharmaceuticals, food and beverage processing and electronics manufacturing, among many others, the purity of gases is paramount. Even trace amounts of hydrocarbons can compromise product quality, affect equipment performance, and jeopardise overall process efficiency. Our FR series adsorbing filters are engineered to ensure the highest levels of purity and reliability, meeting stringent industry standards and regulations.

The versatility of the FR series filters enables their integration into diverse gas handling systems, accommodating a wide range of flow rates and operating conditions. Whether used in heat treatment and tank blanketing applications to maintain inert atmospheres or in welding and cutting applications where precise gas purity is critical for achieving optimal weld quality and operational safety, our adsorbing filters play a crucial role in ensuring that gases used in these processes are free from hydrocarbons.

BSL Adsorbing Filters

What options are available?

FR133F

Dimensions:

200 mm x 82 mm x 82 mm

Weight:

1 kg

FR163F

Dimensions:

200 mm x 82 mm x 82 mm

Weight:

1 kg