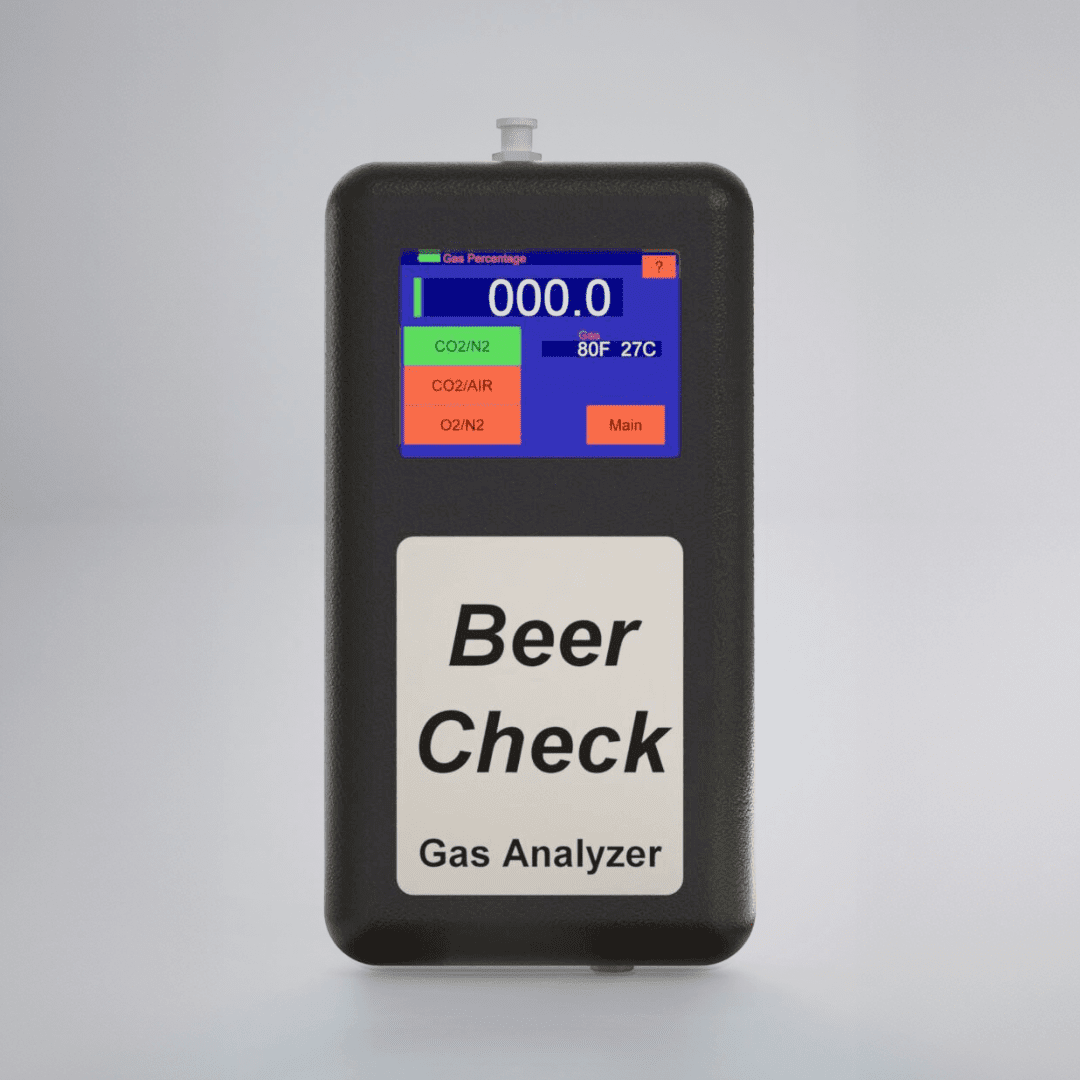

Beer Check Gas Analyser

For accurate gas analysis in beverage dispensing applications

The beer check gas analyser was created to help beer brewers, distributors and end users check the quality and mixture of gases used to serve their beverages.

Dimensions

76.2 mm x 152.4 mm x 44 mm

Weight

0.32 kg

Analysis Gas

CO₂ / N₂ / mixed gas

Sampling Frequency

Continuous

Battery

Rechargeable lithium battery

Connector

1/4″ polypropylene hose barb

-

All gas mixing products supplied by BSL Gas Technologies Ltd are produced in accordance with a BS EN 1SO 9001:2015 accredited quality system.

All gas mixing products supplied by BSL Gas Technologies Ltd are produced in accordance with a BS EN 1SO 9001:2015 accredited quality system.

The Beer Check

What are the key features?

-

Small and light design for portable gas analysis

Small and light design for portable gas analysis

-

Rechargeable battery

Rechargeable battery

-

No mains electricity supply required during analysis

No mains electricity supply required during analysis

-

USB wall charger

USB wall charger

-

Compatible with any 5v USB power source

Compatible with any 5v USB power source

-

Touch screen display

Touch screen display

-

Gas temperatures displayed in Fahrenheit and Celsius

Gas temperatures displayed in Fahrenheit and Celsius

What does it do?

The beer check gas analyser was created to help beer brewers, distributors and end users check the quality and mixture of gases used to serve their beverages. For manufacturers, the Beer Check analyser offers precise control over the dispensing process, ensuring consistency in flavour and aroma.

Distributors benefit from the ability to verify and maintain the quality of beer during storage and transportation, guaranteeing that it reaches consumers in top condition. For end users such as bars and restaurants, the analyser ensures that every pour meets high standards, enhancing customer satisfaction with each pint served. By optimising gas usage and maintaining quality, the beer check gas analyser supports every step of the beer supply chain in delivering a consistently superior drinking experience.

The Beer Check unit can be used to check the gas mixtures of carbon dioxide (CO₂) in nitrogen (N₂) used for beer dispensing and other carbon dioxide (CO₂) and nitrogen (N₂) only applications. The Beer Check gas analyser can also be used to check the presence of oxygen (O₂) in the output of nitrogen generators (N₂) and identify leaks in gas mixing systems.

Display Modes

What options are available?

Mode 1

Mixture percentage (%) of carbon dioxide (CO₂) in nitrogen (N₂)

Mode 2

Percentage (%) of carbon dioxide (CO₂) in air when flushing a keg after cleaning

Mode 3

Percentage (%) of residual oxygen (O₂) in output of a nitrogen (N₂) generator