In November 2014, we were approached by Roots Machinery Laboratories, Inc. to design a custom gas mixer for one of Tokyo’s biggest brewpubs. Here’s how it went:

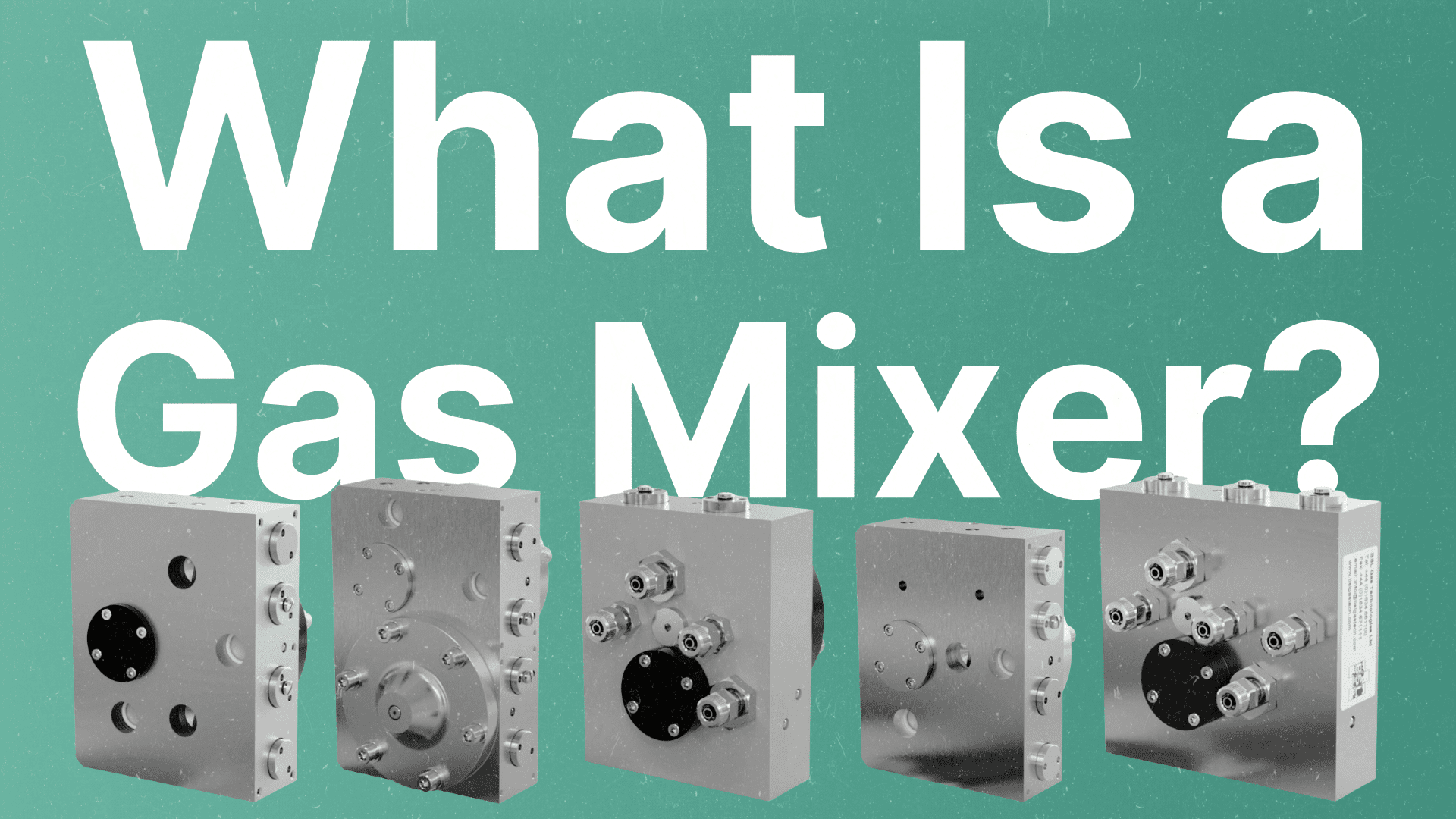

In the past 30 years, BSL Gas Technologies has successfully built hundreds of thousands of gas mixers and gas mixing systems for a range of applications.

In brewing, the most frequented gas mixtures fall into two main types: 30/70 and 60/40. These numbers represent the composition of CO₂ and N₂ in the mixture. For example, a blend of 30/70 (ideal for nitro stouts) comprises 30% CO₂ and 70% N₂, while the 60/40 variant is composed of 60% CO₂ and 40% N₂.

Whether you prefer adhering to industry-standard ratios, or you desire a customised blend tailored to your specific requirements, our gas mixers allow you to craft your brew with precision, enabling you to make it exactly the way you would like it.

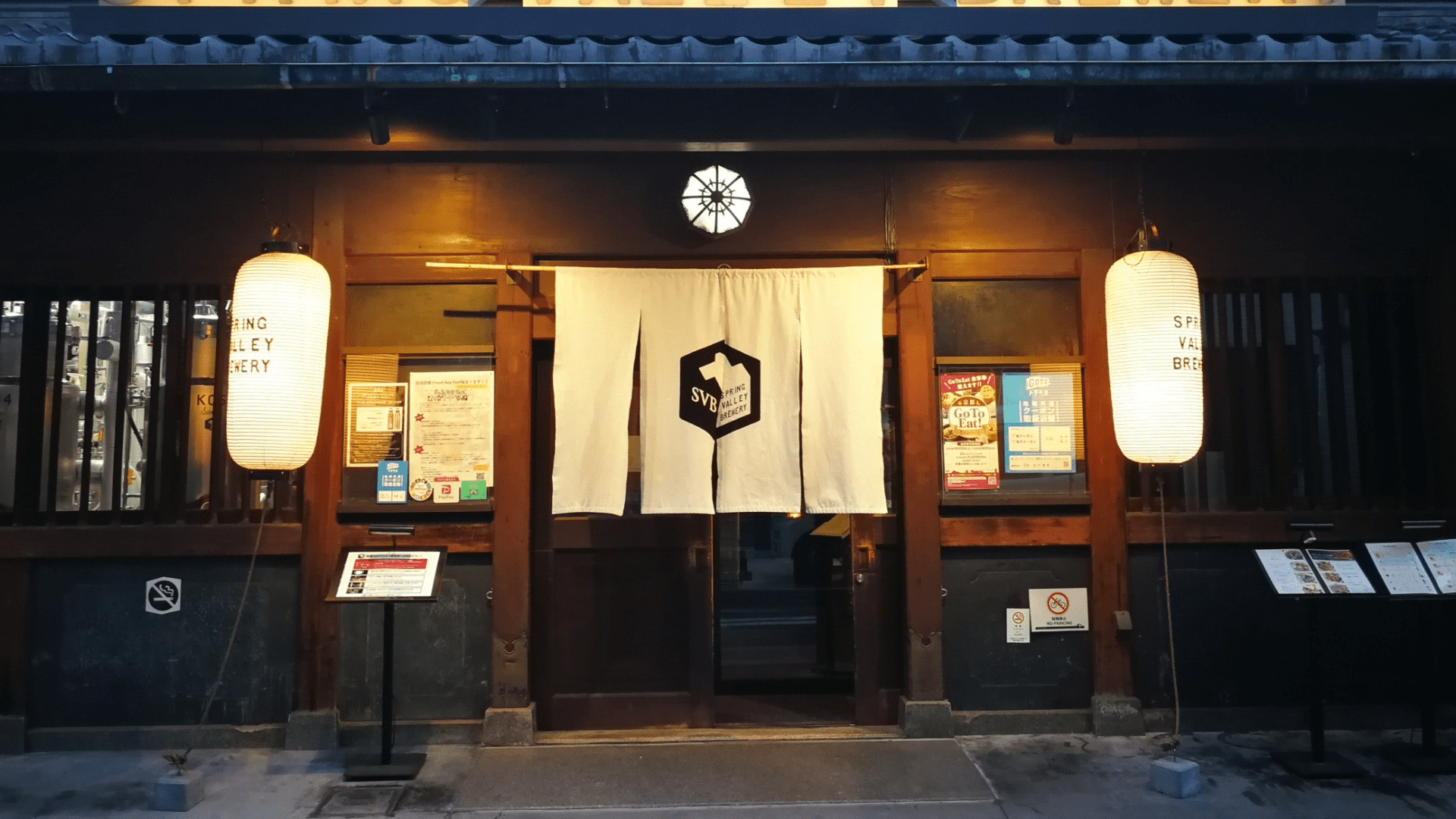

In November 2014, we were approached by Roots Machinery Laboratories, Inc. with a project commissioned by Kirin Brewery Company Ltd. The task was to produce two gas mixing panels for a unique beer dispenser they had created – the ‘Beer Infuser‘ – that could infuse various ingredients into beer, allowing bartenders to customise the beverage to a customers’ preference without causing oxidation or degassing. This cutting-edge Beer Infuser was set to be installed in Spring Valley Brewery, one of Tokyo’s largest brewpubs.

The customer was eager to explore the potential for adjusting the mixing rate to enhance the quality of the beers served. Recognising the need for flexibility, the Research and Development team opted for adjustable mixed gas outlets.

To address the noise concerns associated with traditional air compressors in a pub setting, they requested 100% N₂ outlets for the pneumatic control valves of the Beer Infusers. Given the limited space in both pubs, our client emphasised the need for the panels to have the smallest possible dimensions.

One panel, intended for use in Tokyo, was to be equipped with both N₂ and CO₂ inlets, allowing it to independently output four mixed gases through four regulators and valves. A crucial feature of the client’s request was the need for an adjustable mixing rate, particularly a ratio of 20% CO₂ to 80% N₂. Additionally, the panel was to include a single outlet with a regulator and valve designed for 100% CO₂.

For Panel number 2, destined for deployment in both Tokyo and Yokohama, the client reiterated the specifications of Panel 1 but with a modification in the number of outlets – five, instead of four, for mixed gases. The client’s detailed specifications aimed to ensure precise control and flexibility in the gas mixing process to meet the unique requirements of their brewing operations. The customer also requested a sampling tap, along with a Beer Check for each outlet.

One of our guiding principles has always been customer satisfaction. We take every project as a opportunity to showcase our expertise and our approach to bespoke designs begins with a thorough understanding of the customer’s unique requirements. Based on these inputs, we employ our in-house engineering expertise to create a design that meets the customer’s specifications and we do this while optimising performance, reducing costs and ensuring compliance with industry standards.

Our team worked diligently to design, prototype and produce two different mixing panels for the customer that met their specific net requirements and the final panels met those requirements precisely.

To ensure the panels could fit into the confined space of the brewpub, we custom-designed each panel with 1 outlet of 100% N₂, 1 outlet of 100% CO₂ and 4 outlets of mixed gas. It occurred to us that two of this type of panel, when used together, would give you the capability needed for ‘Panel 1’ or ‘Panel 2’, with one extra 100% CO₂ outlet to use later if needed. We then applied the same logic to ‘Panel 3’, one panel of the above design and one smaller panel with 100% N₂ and 2 outlets of mixed gas. Amidst all of this, we ensured the solution remained cost-effective and provided the customer with the desired flexibility.

By implementing customised solutions to meet specific needs, we were able to deliver a product that was tailored to the customer’s requirements at a competitive price point. In our communications with Takuya Watanabe of Kita Sangyo Co., Ltd. / Roots Machinery Laboratories, Inc., informed us that the technician who visits the site for maintenance claims the panels are still running without issues, 9 years on. We’d like to thank Mr Watanabe for letting us use his testimonial and we hope the panels continue to serve his customer well for many years to come.

If you’re an industry professional who’s serious about perfecting your gas mixing process, you need a gas mixing panel that makes things precise and efficient.

Devising innovative gas mixing solutions is an integral part of our engineering philosophy and we take pride in our ability to deliver excellent customer service. Our systems are flexible and customisable and our team of highly experienced engineers and technicians use their skills and expertise to optimise performance, reduce costs and deliver a product designed to meet our customers’ unique needs. Get in touch with us today via solutions@bslgastech.com or give us a call on 01634 661100.

If you’re interested in reading our other blog posts, you can do that here. Make sure you’re following us on LinkedIn, Facebook, Twitter and YouTube so that you never miss an update from us.