CellarMix Panel

Beverage Dispensing System

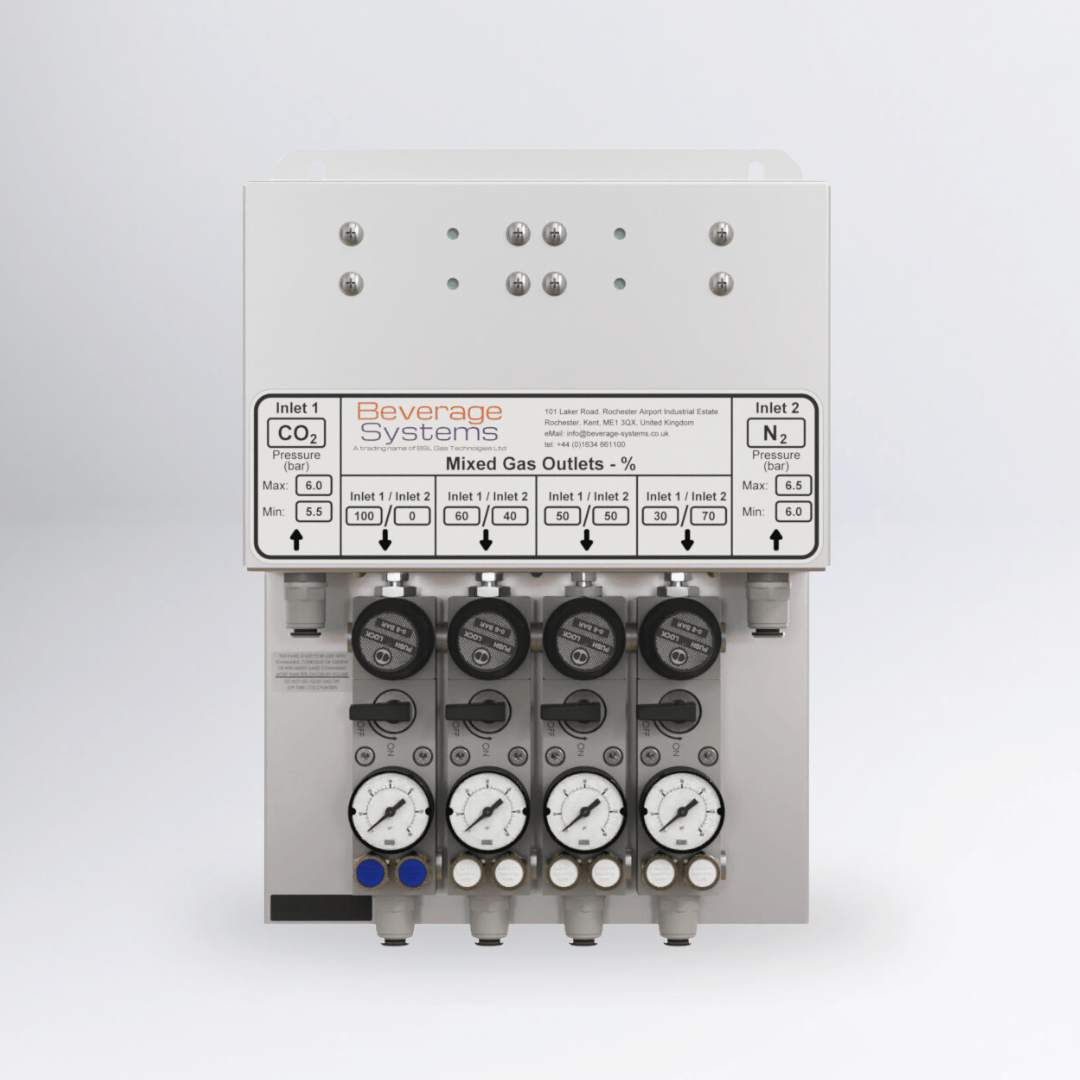

Built to mix CO₂ and N₂ for breweries and pub cellars, the CellarMix panel is a fully mechanical, gas-pressure-balanced gas mixing panel designed to dispense gases up to 4 bar g.

Dimensions

385 mm x 270 mm x 118 mm

Weight

4.5 to 5.2 kg

Supply Gases

CO₂ / N₂ / mixed gas

Design Pressure

13 bar g

Outlet Options

Up to 4 mixed gas ratios

Inlet and Outlet Connections

3/8 Tubing (Push-in fittings)

-

All gas mixing products supplied by BSL Gas Technologies Ltd are produced in accordance with a BS EN 1SO 9001:2015 accredited quality system.

All gas mixing products supplied by BSL Gas Technologies Ltd are produced in accordance with a BS EN 1SO 9001:2015 accredited quality system.

The CellarMix Panel

What are the key features?

-

Fully customisable

Fully customisable

-

Sized to your application

Sized to your application

-

Pre-set and certified for optimal mixed gas configurations

Pre-set and certified for optimal mixed gas configurations

-

Optional flow rate adjustment

Optional flow rate adjustment

-

Self-contained, compact design with a durable stainless steel back-plate

Self-contained, compact design with a durable stainless steel back-plate

-

Low-pressure outlet gas regulators

Low-pressure outlet gas regulators

-

Up to 4 mixed gas outlets per panel

Up to 4 mixed gas outlets per panel

What does it do?

Our popular CellarMix panel range is specially designed to mix beverage dispensing gases in accordance with the Beer Dispense Code of Practice. Our panels allow for the adjustment of mixed gas outlets to any flow rate from 1 Nm³/hr to 2.4 Nm³/hr, ensuring optimal performance across a wide range of applications. By fine-tuning flow rates and mix ratios interconnecting our CellarMix panels, you can achieve unparalleled flow rates and maximise efficiency.

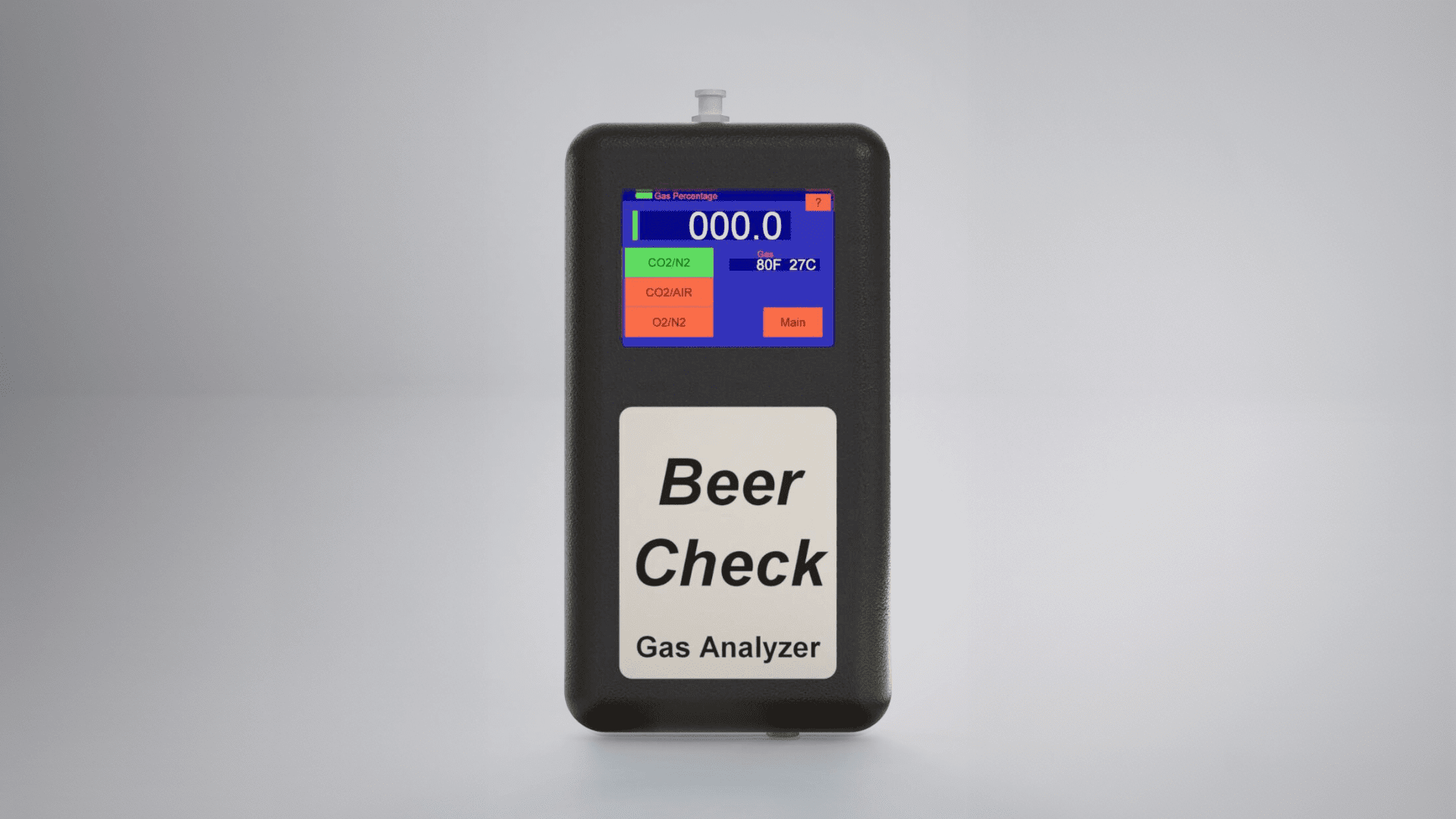

BSL’s standard single CellarMix panel comes equipped with four mixed gas outlets. Additionally, we offer panels with customisable outlet numbers and additional features such as stands, cellar leak detectors, analysers, and a gas sample point for in-depth analysis.

The CellarMix panel offers a self-contained, low-maintenance solution for beverage dispensing, providing a reliable and efficient means of gas mixing for your establishment’s needs.

Pubs & restaurants

Our gas mixers are used to dispense beverages from draft systems, ensuring customers receive the perfect pint every time

Distribution centres

Our gas mixers are used to adjust the carbonation levels of bulk quantities of beverages before shipping to consumers

Breweries

Our gas mixers are used to precisely control the carbonation levels of beer and other beverages

Coffee shops

Our gas mixers are used to produce and dispense nitrogen-infused coffee beverages, creating a smooth and creamy texture

Bottling plants

Our gas mixers are used to carbonate soft drinks and beverages before packaging

Leisure venues

Our gas mixers are used to dispense cocktails and other mixed drinks from draft systems

Mixed Gas Ratios

What options are available?

CM1001 - 1 Outlet Blend

Inlet Gases:

CO₂ / N₂

Mixed Gas Ratios:

30% / 70%

CM1002 - 2 Outlet Blends

Inlet Gases:

CO₂ / N₂

Mixed Gas Ratio:

30% / 70%

60% / 40%

CM1101 - 2 Outlet Blends

Inlet Gases:

CO₂ / N₂

Mixed Gas Ratio:

30% / 70%

100% CO₂

CM1102 - 3 Outlet Blends

Inlet Gases:

CO₂ / N₂

Mixed Gas Ratio:

30% / 70%

60% / 40%

100% CO₂

CM1103 - 4 Outlet Blends

Inlet Gases:

CO₂ / N₂

Mixed Gas Ratio:

30% / 70%

60% / 40%

50% / 50%

100% CO₂