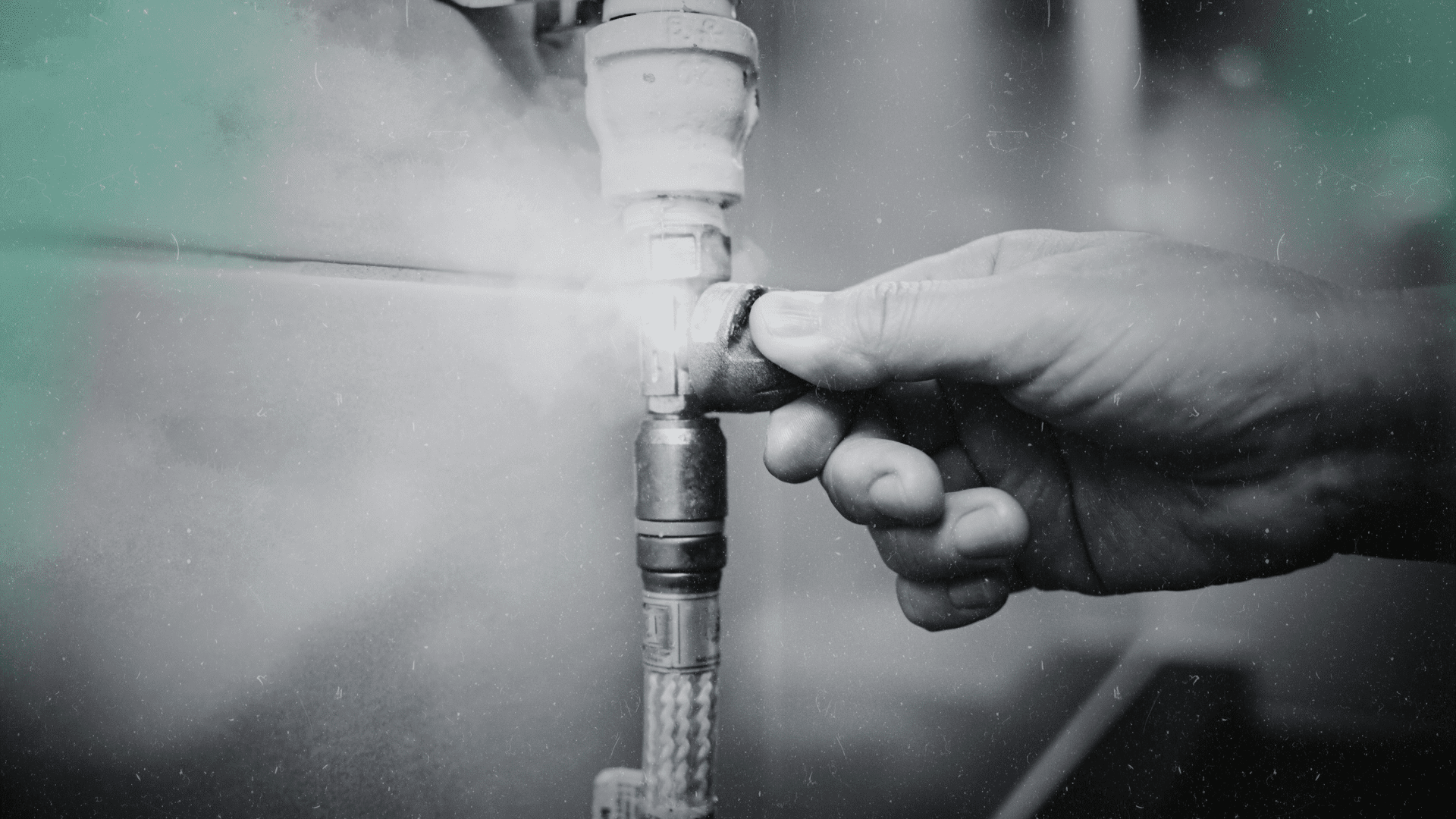

All gases pose potential risks to life, even those we encounter daily. While some gases, like hydrogen, are widely recognised as hazardous due to their flammability, many seemingly harmless gases can also create life-threatening situations if not handled properly.

In this article, we’ll talk about some of the most dangerous gases, the risks they pose and how the right gas mixing equipment can mitigate these risks.

The Dangers of Common Gases

Nitrogen (N₂) – Nitrogen is a colourless and odourless gas that makes up about 78% of the air we breathe. While nitrogen itself is not toxic, it can become dangerous in confined spaces or in high concentrations. Excess nitrogen displaces oxygen, leading to oxygen deficiency—a risk factor in many industries. Workers exposed to nitrogen in enclosed environments risk asphyxiation due to a lack of breathable air.

Carbon Monoxide (CO) – Carbon monoxide is a colourless, odourless gas that is highly toxic. Even at low concentrations—around 200 parts per million (ppm)—CO can cause symptoms such as dizziness, confusion and headaches. Prolonged exposure can lead to unconsciousness and even death. Carbon monoxide binds to haemoglobin in the blood, preventing oxygen from reaching the body’s tissues and organs. It is especially hazardous in confined spaces where it can accumulate quickly.

Carbon Dioxide (CO₂) – Commonly used in soft drink production, carbon dioxide may seem harmless, but it is dangerous in high concentrations.

CO₂ is heavier than air and has a tendency to sink to the lowest point in a room. In a confined space like a pub cellar, this means that any CO₂ leaks will accumulate at ground level, making it even more hazardous for workers who may not be able to detect its presence until it’s too late. Proper ventilation and gas detection equipment, along with regular maintenance of gas cylinders and lines, are crucial in preventing potentially life-threatening situations.

Nitrogen Dioxide (NO₂) – Another dangerous gas that can be found in industrial environments is nitrogen dioxide. Exposure to NO₂ levels as low as 100 ppm can irritate the respiratory system, causing coughing and shortness of breath. Long-term exposure can lead to chronic respiratory conditions. In confined spaces, NO₂ poses an even greater risk due to its ability to quickly build up to toxic levels.

Hydrogen Sulphide (H₂S) – Known for its distinctive “rotten egg” smell, hydrogen sulphide is a highly toxic gas that occurs naturally in oil and gas production environments. It is particularly dangerous because it can quickly paralyse the nervous system. Even at concentrations as low as 100 ppm, exposure to H₂S can result in symptoms such as nausea, dizziness and respiratory failure. In high concentrations, hydrogen sulphide can lead to immediate death. It is also highly flammable, adding another layer of risk in confined spaces where it is present.

Understanding The Problem

Understanding the characteristics of these dangerous gases is only part of the solution. To truly ensure safety, industries must employ precise gas mixing equipment designed to regulate gas concentrations accurately.

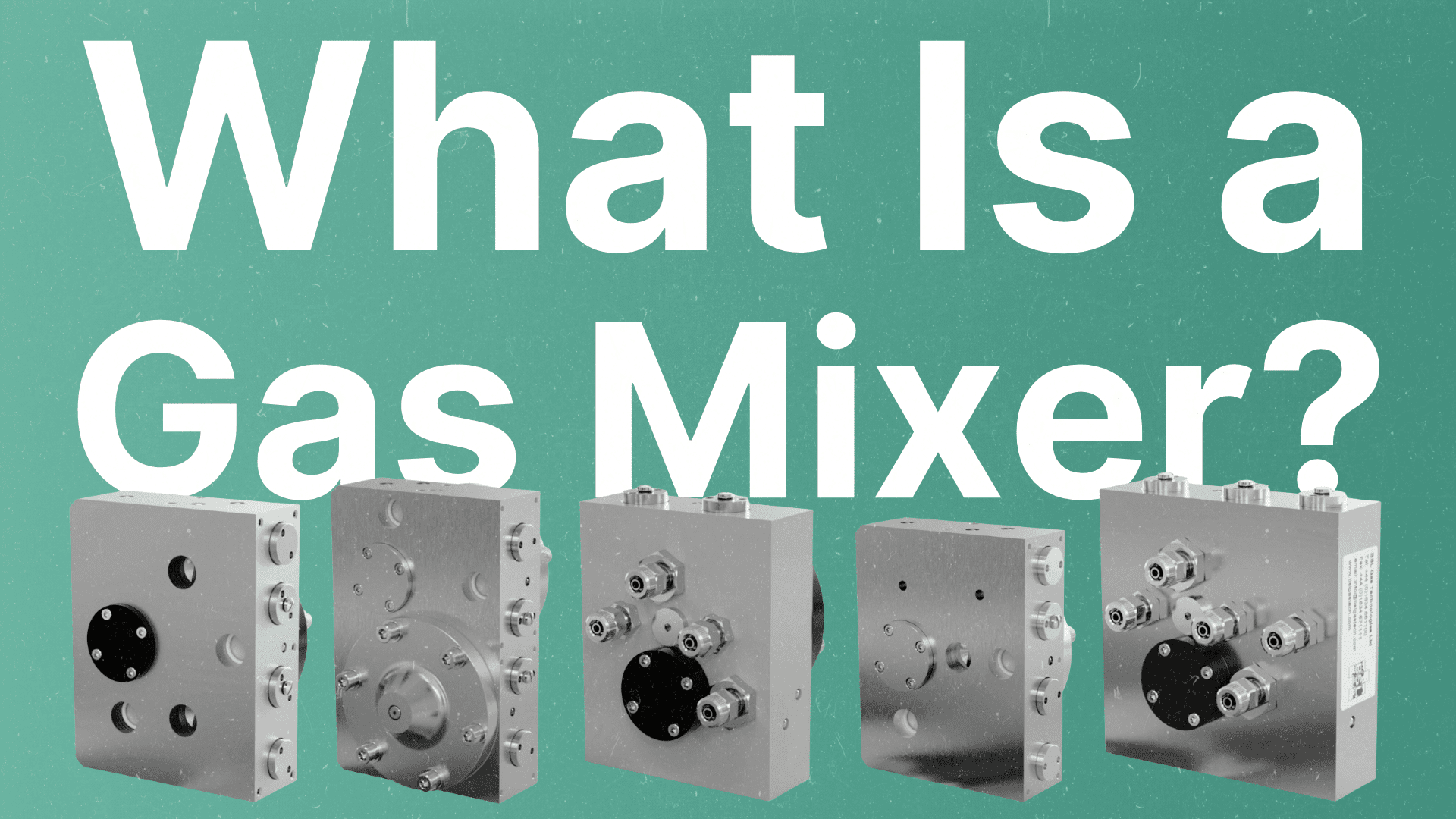

When handling gases such as carbon monoxide, hydrogen sulphide and nitrogen dioxide, precise gas control is critical to avoiding dangerous concentrations. We design advanced gas control systems that are built to handle a wide range of industrial gases, ensuring safety and optimal ratios for every application. Regardless of the industry you’re in, if you’re working with more than one gas, accurate and reliable equipment is essential for maintaining safe and breathable air levels.

Managing The Risks

In many industrial environments, dangerous gases occur naturally, making them difficult to detect without proper monitoring and equipment. By utilising reliable, accurate gas mixing equipment, companies can ensure they are not only compliant with safety standards but are also actively protecting their workers from harmful gas exposure.

We design our gas mixers to handle highly toxic and flammable gases with precision. This ensures that whether you’re dealing with toxic gases like hydrogen sulphide or nitrogen dioxide, or common gases like carbon dioxide and nitrogen, you can successfully mitigate the risks associated with gas exposure.

Investing in high-quality gas mixing equipment is not just about efficiency—it’s about safeguarding the health and welfare of those in environments where gases are present.

Who Are We?

We are BSL Gas Technologies, an ISO 9001:2015 accredited UK manufacturer of gas mixing and control equipment, based in the UK. With more than 30 years of experience, we design and manufacture bespoke gas mixing solutions and are committed to meeting both our customers’ expectations and the safety standards required for their businesses.

With our global reach and industry expertise, we serve our gas mixing solutions to essential sectors in over 75 countries around the world. The applications of our gas mixing solutions are diverse, ranging from automotive and aerospace to industrial and food processing industries and more.

We centre our approach around problem-solving, pride ourselves on our commitment to customer satisfaction and commit ourselves to engineering excellence, quality delivery performance and continuous improvement.

What to Do Now

Get in touch with us today.

We’re here to help you with all your manufacturing and engineering needs. If you can’t see what you’re looking for on our website, don’t worry, we also offer bespoke gas mixing projects.

If you’re interested in reading our other blog posts, you can do that here. Make sure you’re following us on LinkedIn, Facebook, Twitter and YouTube so that you never miss an update from us.