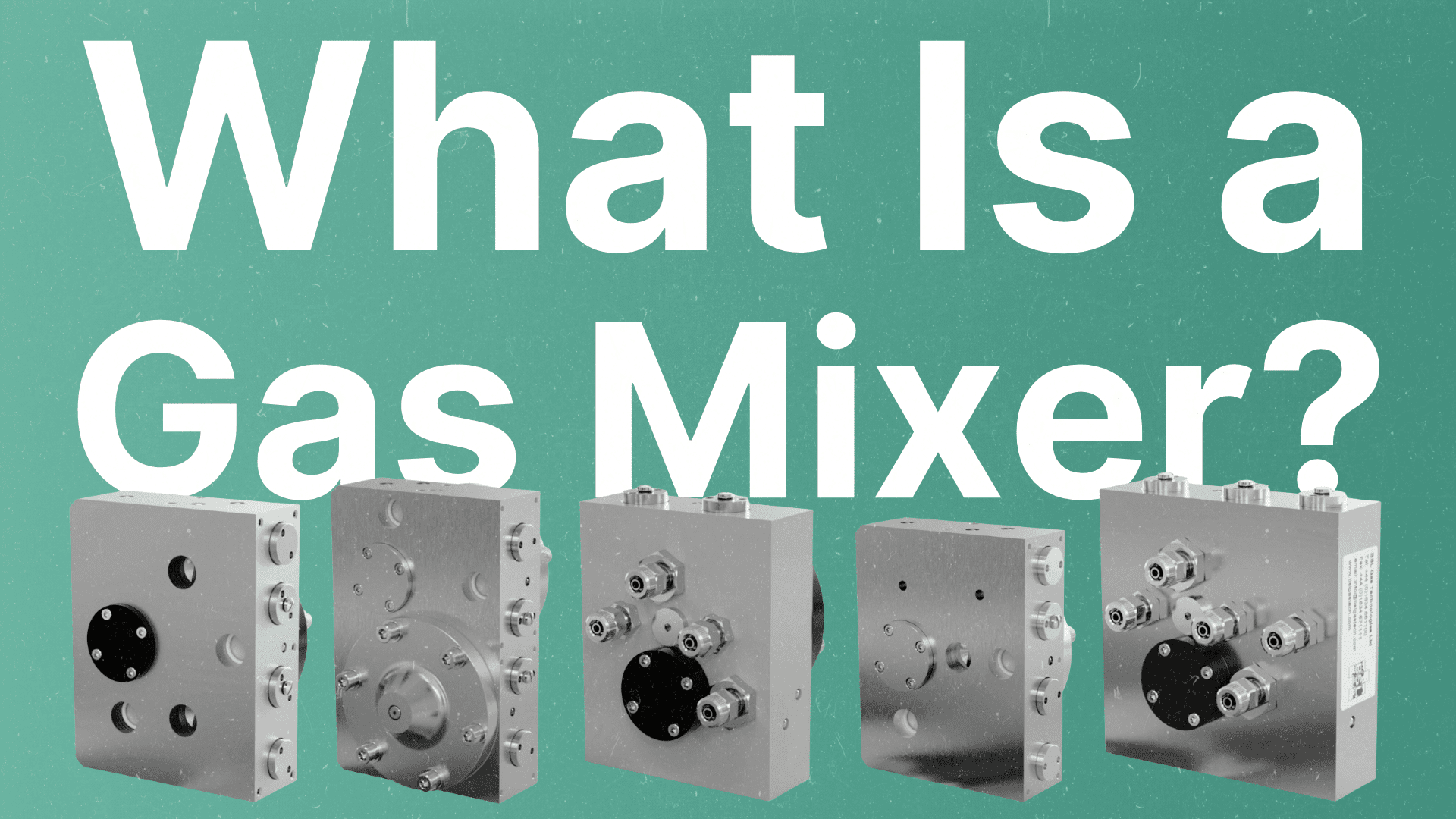

What is Mixed Gas Distribution?

Mixed gas distribution involves blending two or more pure gases in specific proportions to create a customised gas mixture, essential for applications that require precise gas compositions. The big challenge of mixed gas distribution lies in achieving and maintaining consistent mix ratios while meeting varying demands for gas supply.

The Role of Gas Mixers in Mixed Gas Distribution

Mixed gas distribution plays a vital role across so many industries, from heat treatment applications for metal fabrication and controlled atmospheres used in food processing to healthcare, automotive manufacturing and even aerospace engineering. In these applications, it’s crucial to ensure the correct balance of gases. Without it, maintaining product quality, operational safety and overall efficiency is just simply not possible.

Traditional methods, such as using pre-mixed gas cylinders, offer limited flexibility and can become costly over time. This is where a BSL gas mixer steps in, offering a simple and reliable solution to the gas mixing process.

Why Choose a BSL Gas Mixer?

BSL gas mixers are designed to simplify the complexities of mixed gas distribution. They offer numerous advantages over pre-mixed cylinder gases, including greater flexibility, cost-efficiency and improved process control.

Here’s a closer look at the key features that set a BSL Gas Technologies gas mixer apart:

1. Customisable Gas Mix Options

Unlike pre-mixed cylinders, which come in fixed ratios, BSL gas mixing equipment allows for a wide range of mix options. With both pre-set and adjustable configurations available, users gain complete control over their gas composition, ensuring it suits their specific process requirements.

2. Enhanced Process Integrity

Maintaining the accuracy and consistency of a gas mixture is critical. Our systems come equipped with tamper-evident labels and precision controls, safeguarding the integrity of your gas mix throughout its distribution.

3. Flexibility and Scalability

Our gas mixers support flexibility in process variations, making it easy to adjust to changing operational demands. The modular design of these systems allows for seamless expansion without the need to invest in a larger system upfront. This makes it ideal for businesses anticipating future growth or evolving gas requirements.

4. Simplified Installation

Traditional gas mixing systems often require complex installations involving electrical components or buffer tanks. BSL gas mixers eliminate these complications, featuring a straightforward design that simplifies installation while maintaining operational safety.

5. Safe and Easy Gas Handling

When it comes to mixed gas distribution, safety is our top priority. Our gas mixers are engineered for durability and built to withstand demanding industrial environments. With built-in safety features and tamper-proof mechanisms, users can trust our equipment to provide a regulated and protected supply of mixed gas to their application. This reliability minimises downtime, ensuring smooth operations, even under high demand.

6. Reduced Costs and Improved Sustainability

One of the standout advantages of BSL gas mixers is their ability to reduce operational costs. By enabling on-site gas mixing, businesses can cut down on the need for multiple pre-mixed gas cylinders, which not only saves money but also reduces storage space requirements. This approach minimises waste, as users can produce the exact gas mixture required, avoiding surplus.

Furthermore, by eliminating the need for transporting pre-mixed cylinders, companies can significantly lower their carbon footprint, contributing to more sustainable operations.

Future-Proofing Gas Distribution

As industries evolve, so do their gas requirements. Our modular systems make it easy to adapt and expand, accommodating future growth without major system overhauls. This scalability ensures your business is not only equipped for current needs but is also prepared to meet emerging opportunities.

A BSL gas mixer offers a cost-effective, safe and sustainable alternative to pre-mixed gas cylinders. They are flexible, precise and ease of use, making our equipment an indispensable tool for industries that rely on customised gas compositions. Whether it’s welding, food packaging, or large-scale manufacturing, a BSL gas mixer will ensure reliable performance, enabling you to thrive in today’s fast-paced industrial environment.

To find out more about our gas mixing panels and how they work, or to chat about your business’s gas mixing needs, you can get in touch with our team today by calling +44 (0) 1634 661100 or sending us an email at solutions@bslgastech.com.

If you’re interested in reading our other blog posts, you can do that here. Make sure you’re following us on LinkedIn, Facebook, Twitter and YouTube so that you never miss an update from us.